Designed to protect guide-ways and machine components and constructed using lightweight material, bellow covers are ideal for fast travel applications. Their high compression ratio also makes accordion way covers ideal in limited space.

Our bellows are made exclusively from high-quality plastic fabrics and foils. We select the cover material and processing according to the design ambient conditions. Decisive factors are the mechanical and thermal strain of the bellows as well as the type of swarf, chips, and aggressiveness of the agents used.

Our product range includes simple dust protection, sophisticated designs featuring extension systems and/or lamellas, as well as special designs for laser machines. To maintain our high quality standards, all materials used are checked and developed by our own R & D departments. Hennig offers excellent productivity and security for your machine.

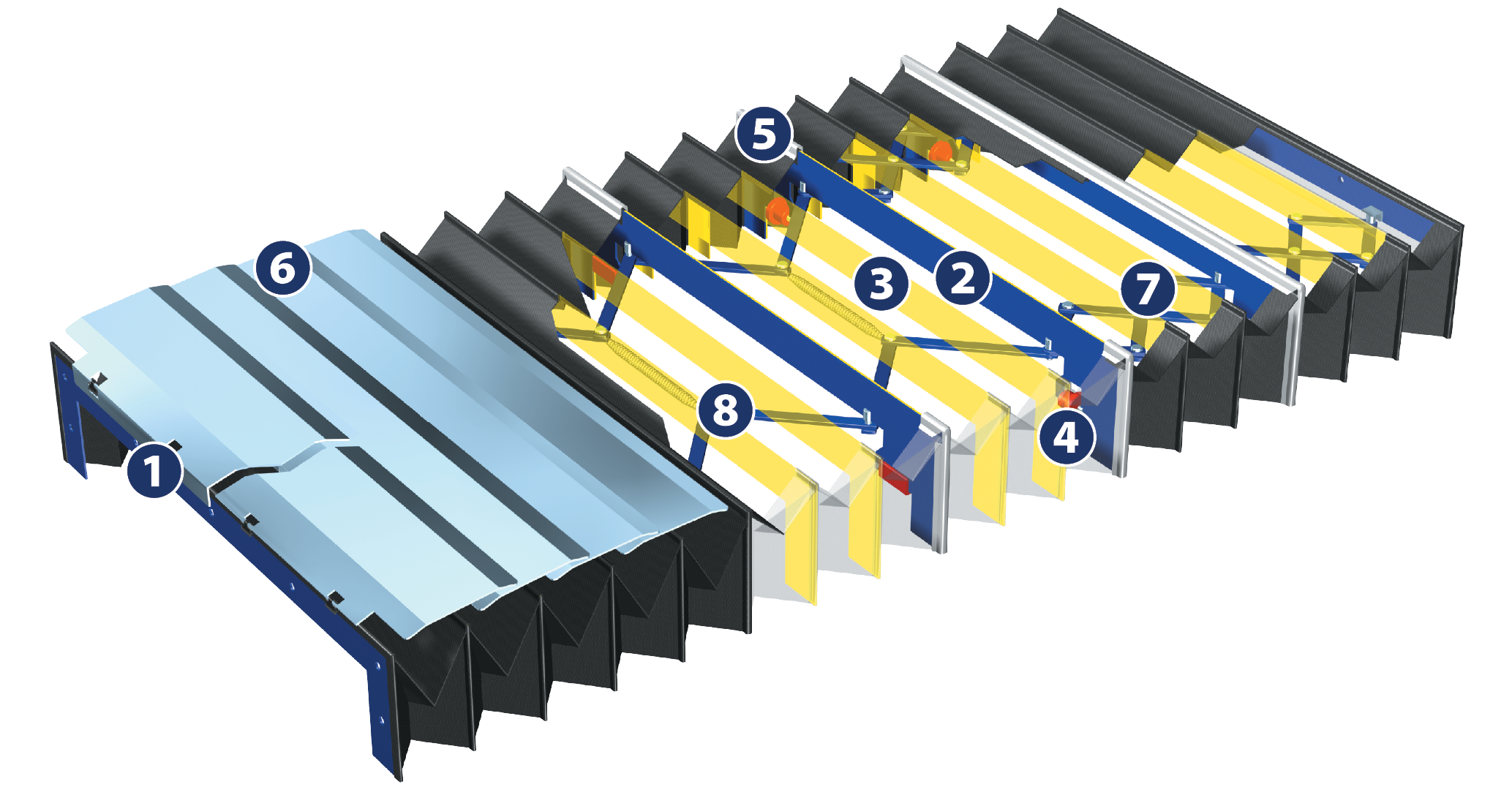

BELLOWS OPTIONS

The dynamic properties of modern drives make heavy demands on all bellows. With Hennig, you can adapt every detail of the friction, extension and durability properties of your bellows to your requirements.

- End Frames

End frames, mostly made from steel or aluminum, connect the bellows with the machine. Hennig offers various fastening solutions for the adaptation to different bellows and machine interfaces. - Intermediate Frames

Intermediate steel frames are used to connect the various elements, especially when extension limit systems are required. The intermediate frames are fastened to the bellows with a clamping rail. The intermediate frames can be guided by either plastic or brass rollers or gliders. - Guide Frames

The guide frames provide the bellows with the necessary stability and enable a precise operation, even at high speeds. They are made from PVC and are directly welded to the cover. The shape of the frame is adapted by Hennig to the design required. - Rollers

Rollers are used in large and heavy bellows. They minimize friction and ensure excellent running properties. - Coupling Rail

Necessary for medium and large bellows with a high number of folds in order to connect the single bellow elements together. Connected inside and outside. - Lamellas

Fixed or hinged, stainless steel lamellas can be added to protect the bellows against hot, sharp-edged swarf, or mechanical strain. - Scissors

Scissors are used for high traversing speeds. This allows an even extension of all elements across the whole extension length. As a result, the folds are less strained and the durability of the bellows is prolonged. - Half Scissors

With half-scissors, the individual elements can be extended successively depending on the necessary extension length. Since the folds are not loaded up to the theoretically possible extension limit, it also has better durability.

Assembly Options

HEAT SEALED

The optimum design for bellows is the heat-sealed version. The cover material and PVC guide frames are permanently joined. The connection of the bellows material and the guide frames ensures maximum loading capacity and absolute tightness against liquids such as cooling or grinding agents.

STITCHED

Due to their robust design, these bellows have a long and reliable service life, even under extreme mechanical and dynamic strain. The temperature resistance of these bellows can be increased to approx. 400 °C (752 °F) when using an aluminized fabric.

GLUED

These bellows consist of up to three foils glued together in sandwich construction. Due to the special gluing of materials, these bellows provide maximum protection, even against liquids.

BELLOWS FAQ

Why do you need bellows?

Bellows are used as machinery protection in a wide variety of industries. Their primary use is to protect guideways and other precision equipment from outside contaminants and occasionally to keep contaminants contained. They often have a secondary purpose as a visual barrier to protect pinch points and other areas where machinery could prove dangerous to a user.

What types of bellows are there?

Hennig sells and designs different types of bellows for different applications. These bellows could range from simple heat sealed bellows to run on a rail to a sewn round bellow to protect a ball screw or a bellow with stainless steel shims to protect the bellow from hot chips or molded bellows to protect a piston. Bellows can literally come in all shapes and sizes. These bellows could range from:

- Simple heat sealed bellows that run on a rail

- A sewn round bellow to protect a ball screw

- A bellow with stainless steel shims to protect the bellow from hot chips

- Molded bellows to protect a piston

Which bellow is the right one?

You may already know the correct bellow for your application but, if you don’t, then you can talk to our engineers or sales directors who will guide you through materials, types of bellows, and other criteria depending on the conditions or the application.